Technology

- HOME

- Technology

Plant Engineering

Component Equipment

JCEM Engineering

As time goes by customer needs at their plants grow more complex and diverse. The integration of the various technologies we have developed though past achievements and experience enables further development, and we have also been able to set up a business management system for use in satisfying customer requests to higher level.

JCEM Vietnam Co., Ltd. always gives the answer to customer needs.

Plant Engineering

Component Equipment

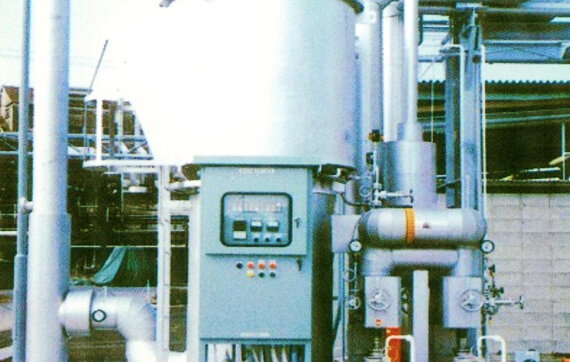

Alcohol Distillation Plant

Alcohol distilling system: Potable and industrial alcohol distillation systems are one of our strongest fields. The photo indicates a system delivered to TAKARASHUZO Co., Ltd., which has adopted revolutionary processes with the aim of improving alcohol quality, saving more energy, and achieving full automation through the introduction of an integrated distributed control system. We take responsibility for carrying out everything from design and manufacturing to on-site construction work and commissioning.

Absolute alcohol distillation system: This continuous absolute-alcohol recovery system uses cyclohexane as a dehydrating agent. The system attains purity as high as 99.96%, and recovers a trace amount of high-quality ester incidentally distilled in the reaction process.

Ammonia Stripping Plant

We merge some of our technologies, including catalytic deodorizing technology, stripping technology, absorption technology, and wastewater treatment technology, to offer a solution for nitrogen control in any wastewater and exhaust gas.

We offer various solutions for nitrogen control in wastewater. We developed a system by merging a high-performance, field-proven stripping tower and catalytic deodorizing technology that uses an ammonia treatment catalyst, and offer and implement a method of treatment using this system and a method for recovering ammonia water that combines the use of a stripping tower and an absorption tower.

Reactor

With various chemical factories reaction processes occupy the most important position in regard to manufacturing products that have a lot of added value, are of high quality, and high purity at low cost. As a manufacturer specializing in chemical plants, we have been involved in the construction of many sets of reactor over a number of years. In particular, we have been delivering many sets of equipment to resin manufacturing plants for a long time.

With more added value and better quality being prerequisites for products in the future, we are continuing to quickly respond to the needs of customers and to construct the equipment that fully satisfies the needs.

Evaporation & Concentration Plant

Through the process of removing solvents from solutions by evaporation and boiling, evaporators and concentrators have been extensively used as key equipment in a wide range of sectors and industries, from water and waste treatment to chemical manufacturing, food, and pharmaceuticals processing as well as paper and pulp industries. With our years of expertise and outstanding achievements throughout our operation since our establishment, our professional engineering team will consult, select, and design the most suitable type of system based on design parameters and output products as desired by customers, with the goal of achieving economic efficiency, minimizing operating costs through efficient use of energy in combination of automatization.

Solvent recovery system

The system performs fully automatic recovery of solvents for chemicals, medicines, food, paints, etc. as well as the recovery of cleaning solvents used in the industries such as electromagnetic components and precision machinery. It offers a high recovery rate, short treatment time, and recduced running cost.

Absolute alcohol distillation system

This continuous absolute-alcohol recovery system uses cyclohexane as a dehydrating agent. The system attains purity as high as 99.96%, and recovers a trace amount of high-quality ester incidentally distilled in the reaction process.

Calandria type concentration system

While standard calandria type evaporation system are widely used as the typical concentration evaporator by the various food and chemical industries, we have delivered many of those system finishing concentration evaporators especially for sugar solutions and starch syrups.

Catalytic deodorizing equipment

Our catalytic deodorizing equipment uses a precious metal catalyst to completely decompose foul odors, fermentation odors, ammonia odors and VOC (volatile organic solvent), which have previously been considered difficult to deodorize.

We have catalysts dedicated to foul odors, fermentation odors, and ammonia odors and catalysts dedicated to VOC (volatile organic solvent). Either or both of them can be selected depending on the details of the deodorization treatment needed.

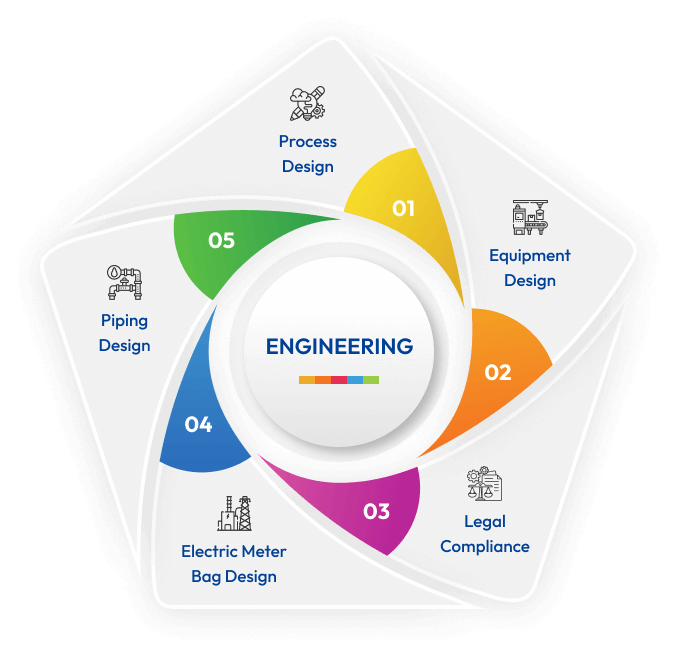

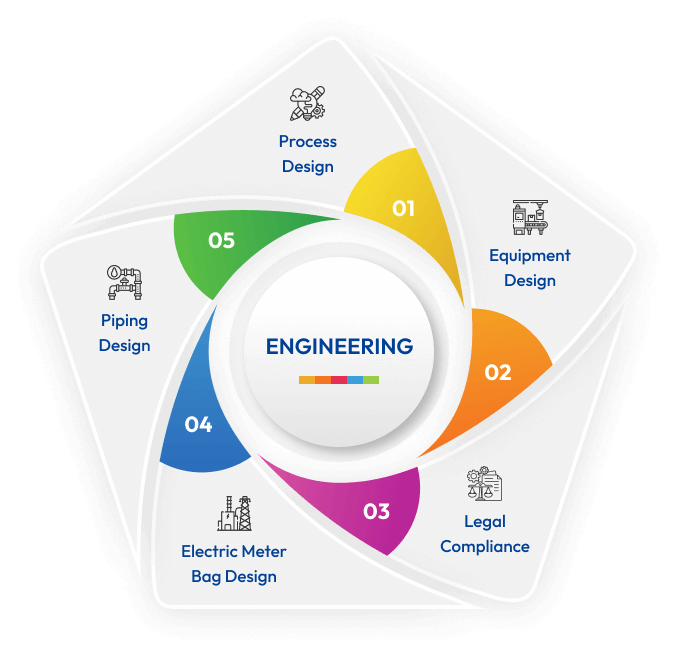

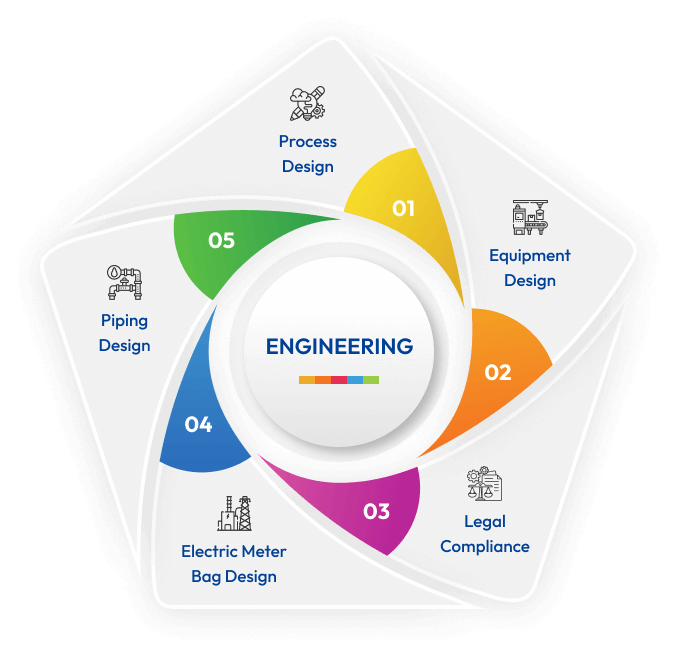

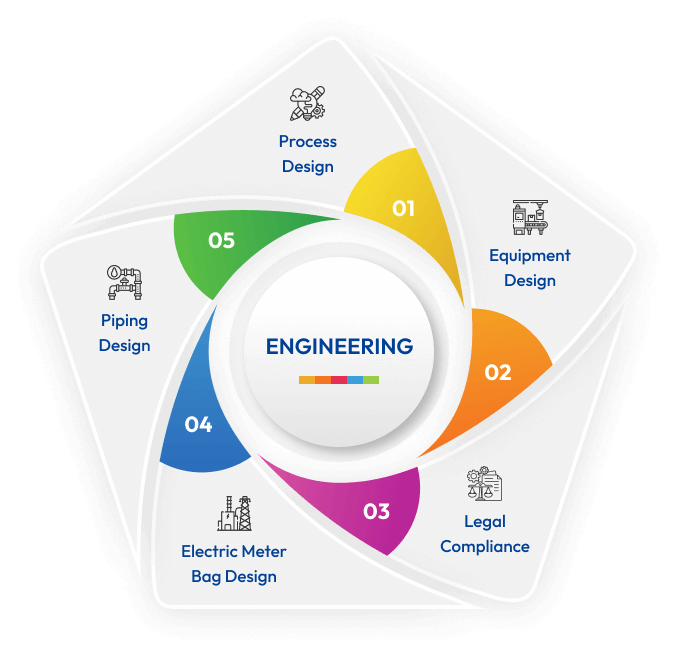

JCEM Engineering

As time goes by customer needs at their plants grow more complex and diverse. The integration of the various technologies we have developed though past achievements and experience enables further development, and we have also been able to set up a business management system for use in satisfying customer requests to higher level.

JCEM Vietnam Co., Ltd. always gives the answer to customer needs.

Plant Engineering

Component Equipment

Distillation Column

Distillation operation has a long history and it started as beverage alcohol industry (some say that it started around 14th century). Distillation plays an important role in refining, separation and recovery processes in the manufacturing process of synthetic organic chemistry industry such as petrochemistry.

Since its foundation in 1938, as a manufacturer specializing in chemical machinery, our company has been dedicated to research and development of distillation technologies. In particular, we have delivered a large number of alcohol distillation systems we developed. Our sophisticated products have been adopted by brewers nationwide and remain highly evaluated by all our customers.

Vessel

We design and manufacture various types of storage tanks for use with liquids, powders, and gases. Our products also include pressure vessels that can withstand any type of condition along with vessels made of special materials such as titanum, nickel, Hastelloy and zirconium. Our services also cover the design and manufacture of various types of mixing vessels that include NX mixers, which provide excellent performance in mixing low right through to high viscosity materials, as well as reactor, evaporator, and fermenter

Boiler

The boilers feature high temperature output at normal pressure but a compact design that requires very little space for installation. They also feature easy maintenance due to the heating coil being easy to remove.

Dryer

The Coulter spray dryer was developed by Dr. Coulter at the University of Minnesota in the U.S., and includes many superior features. The system dries sprayed liquids (solid components) with hot air in a drying chamber. (Also effective as a granulation system)

Heat Exchanger

There are many types of heat exchanger in chemical industry as a device to deal with thermal conduction and it is one of necessary devices in chemical plants. Types and materials of heat exchangers are selected and adopted according to use conditions. Our company produces heat exchangers under strict quality control.

Filter

Our OS filter (continuous vacuum rotating filter) is a cylindrical single-chamber type filter made after improving the multi-chamber type Oliver filter, and was developed with the aim of commercializing a simpler model at lower cost in comparison with the Young filter, in which the cylinder is divided into many sections.

It is a continuous vacuum rotating filter that reduces pressure while rotating a single-chamber filtration drum at low speed and filtrate the substance on the external surface of the drum.

Press Filler dryer

The SN type automatic cake-scraping. Press filter dryer is an innovative system that takes advantage of various structural charateristics to carry out a series of operations that include filtration, cleaning, and drying. In addition, it uses an automatic cake scraping system to easily resurry and to automacitally discharge cake under closed conditions. The specifications of the filter dryer depend on the purpose, but the process is consistent. The key point it how to stramline and ensure the cleaning, drying, and cake discharge processes after filtration. This equipment is a superior filter dryer designed exactly for these purposes.

NX mixer

This newly developed “NX mixer” is an epoch-making system most suitable for mixing liquids from low to high viscosities and for preventing the sedimentaion of solid subtances. Through a number of practical tests, the mixer has further improved its performance and mixing efficiency and is highly evaluated for its energy saving performance.