State of combustion

(pulsation occurs)

While we can provide an indirect air heater (PT air heater), we also offer an air heater with direct combustion system when clean heated air is not necessarily required.

- Air heater with direct combustion system

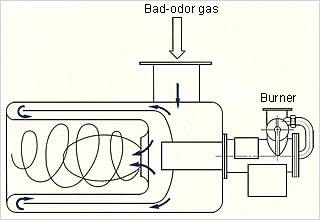

- Deodorizing furnace

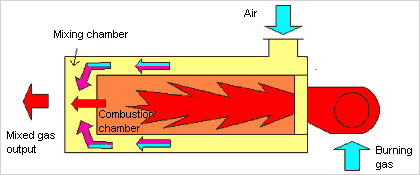

This air heater with a direct combustion system generates heated air of specified temperature by diluting high temperature combustion gas of heavy oil, kerosene, or fuel gas with air. This can be used when users do not necessarily need clean air. The capacity is 200,000 to 20,000,000 kJ/hr and it can generate heated air whose maximum outlet temperature is 1,000°C. With 95% or higher thermal efficiency, it is very economical.

Complete combustion occurs in a combustion chamber and high temperature combustion gas is led to a mixing chamber. Air flows into a space between inner and outer cylinders and cools the inner cylinder while it passes through venturi tube and then enters in the mixing chamber where it is mixed with combustion gas to be specified temperature. Depending on the outlet temperature, sometimes refractory lining is applied.

While the above air heater with a direct combustion system has separate air for combustion and heated mixed air and mixes them in the mixing chamber, a deodorizing furnace (combustor) uses gas with odor as combustion gas (air) and obtains deodorizing effect . The performance of deodorizing furnace with direct combustion system depends on how well and homogeneously it can mix odorous gas and harmful gas. Since the combustion chamber has the special structure, at the same time of mixture combustion, pulsation occurs with flames, which further promotes effective mixed oxidation.

This heater can be used for heating high-pressure air, gas and vapor of 30KPa or higher which cannot be handled with our indirect air heater (PT air heater) series. It is most suitable for heating saturated vapor.

In order to provide pressure resistance structure, fluid (air, gas and vapor) to be heated flows through in the coil. The coil is directly heated and exhaust gas travels through one path from the bottom to the top and emitted to a chimney. In order to absorb expansion heat of the coil, a heating coil is suspended from the top.

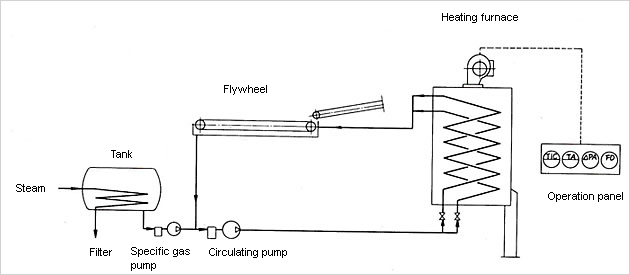

When producing fried foods, in order to resolve a defect of fryer due to furnace installation, an oil circulation heating system with heating coils have been developed taking advantage of our thermal oil heater (heat medium boiler) technique.

- Since circulation type heating coils are used, no local overheating occurs

- Oil content within heating coils is a little (turnover rate of added oil is high)

- Temperature of each heated oil outlet is even

- Only small amount of replacement oil is necessary

- Since thermal efficiency is 80% or higher, energy can be saved

- Since there is no oil pool, chemical cleaning and water cleaning can be done thoroughly

- Double and triple safety devices are provided

- Heavy oil, kerosene, or gas can be used as fuel

This heat exchanger uses combustion gas for preheating air before it is heated by a boiler so that the heat recovery rate can be increased, it can save energy as well.

![[Preheating of air to be heated]](../images/various_img09.jpg)

- [Preheating of air to be heated]

![[Preheating of combustion air]](../images/various_img10.jpg)

- [Preheating of combustion air]