A hydrocyclone (liquid cyclone) is an innovative separator with a very simple structure without a drive unit by injecting the treatment solution into stationary equipment to perform separation, classification, and concentration.

A hydrocyclone (liquid cyclone) is an innovative separator with a very simple structure without a drive unit by injecting the treatment solution into stationary equipment to perform separation, classification, and concentration.

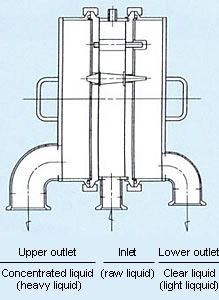

Structure of a hydrocyclone (liquid cyclone)

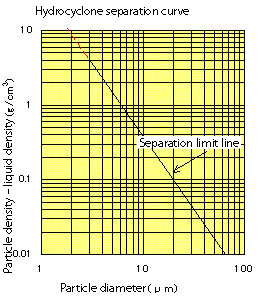

A suspension containing fine particles of several micrometers or more is supplied to a cylindrical container circumferentially at high speed. And as a result it starts to rotate and a centrifugal force is generated. At this time a gravitational acceleration of several tens of thousands of G is generated in the circumferential direction, and thus leading to fast sedimentation and concentration of the fine particles. The separated concentration can be freely selected by changing the supply rate (supply pressure and flow rate) and the flow ratio of the outlet. Our hydrocyclone (liquid cyclone) is designed and manufactured to classify and concentrate fine particles, and so has a small element.

| Type | Casing size | Nozzle size | Maximum processing volume | ||

|---|---|---|---|---|---|

| Cone circumference | Inlet | Upper discharge outlet | Lower discharge outlet | (m3/hr) | |

* The number after the inlet indicates the number of inlets.

* Nozzles attached to inlet and outlet are subject to change according to the upper and lower limits of capabilities.

- Equipment costs can be reduced

- Maintenance costs can be reduced

- Large amounts can be treated in a small area

- Synchronized operation with outer equipment is possible

- Operating costs can be reduced

- Any change in raw material and product can be easily addressed

- Separation and cleaning are easy because of the simple structure

- Simplified control

- Alarm and interlock mechanism

- Classification and concentration for the manufacture of inorganic powder materials

- Removal of fine particles from iron-containing powder

- Removal of fine organic particles from solvents

- Removal of fine particles from high-temperature strong acid solutions

- Classification of ceramic materials

- Removal of fine particles from pigments

- Separation of starch and yeast

- Removal of fine particles from low-temperature solutions