In recent years, attention to the resource and environment has become a strong demand, and the newly-developed “NX Mixer” is a breakthrough mixer which is optimized to prevent sedimentation of mixing which included from low-viscosity liquids to high-viscosity liquids and sedimentation of solid materials. After many repetitive empirical tests, its outstanding performance is highly appreciated in improving stirring efficiency plus conventional equipment and energy saving.

- Efficiency improvement by vertical circulation flow.

(Efficiently performing stirring treatment from low-viscosity liquids to mid-high-viscosity liquids.) - Stirring tank-bottom solid materials retention prevention.

- Mixing/ reaction time reduction.

- Energy saving, space saving improvement.

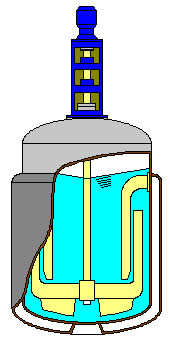

In order to compensate for the shortcomings of the anchor wing, NX Mixer2 series (see figure below) is making a flow which circulates entirely by widening the size of horizontal wing part of the lower anchor wing along with the combination of double helical ribbon wing in the stirring shaft’s center. Moreover, in order to increase shearing force of liquids, the mixing performance at the zone of mid-high-viscosity is being upgraded through a structure in which the anchor wing passes through the baffle plate and the vessel wall. Dynamically it has the same level with a generic wing, but it is a stirring wing which can exhibit stable functionalities within an enabled using region of mixings from lamina flow region to the whole of turbulence. In addition, NX Mixer 1 series (see figure below) can generate a vertical circulation flow inside the tank, prevent the accumulation of the particles at the bottom of the stirring tank, improve the dispersion mixing of solids and liquids by attaching a backspace wing to the horizontal wing part of the lower anchor wing.

- [Mode 1 (Applied for solid-liquid mixing)]

![[Mode 1 (Applied for solid-liquid mixing)]](../images/mixer_img01.jpg)

- As following the above tank-inside flow pattern by attaching a backspace wing to the lower anchor wing, the vertical flow has been added and the stirring efficiency has been greatly improved.

- [Mode 2 (Applied for liquid-liquid mixing)]

![[Mode 2 (Applied for liquid-liquid mixing)]](../images/mixer_img02.jpg)

- Improving the stirring around the shaft and the stirring efficiency by attaching a special helical ribbon wing to the anchor wing.

Note: In the flow figure the swirling flow to the rotation direction which is specified with the anchor wing is not input but this flow is occurring at the same time.

Machinery related to chemical, food, pharmaceutical, fine chemical and IT series.