-

Along with remarkable industrial development, more strict use conditions and corrosion resistance are required for mixing tanks which are used in a wide variety of plants and facilities. We have provided products meeting a large number of customers’ demand. When you consider construction of new plants, updating or scaling up existing equipment or machinery, we would be happy to offer assistance.

Although there are many types of mixing tanks, it is necessary to consider the structure and vane types to cope with the conditions of contents or purposes. We recommend that you make right selections for a variety of options and consider good balance of entire equipment so that mixing tank is able to contribute throughout the entire processes to produce finished products.

According to user’s purposes, basic shape and use conditions are determined. Taking these into consideration including peripheral equipment environment, details of equipment are designed.

Stirring, mixing, dispersion, cultivation, fermentation, reaction, crystallization, etc.

Selecting vane type

- Anchor form

- Paddle

- Turbine

- Propeller

- Also number of phases is to be determined based on liquid depth

Selecting accessories

- Air blower

- CGP

- Shower pipe

- Defoaming vane

- Thermometer tube

And other accessories to be attached inside and outside of equipment

Rotation speed

Vane shape, properties of the content and purpose are important determinants for rotation speed of mixing tanks

Others, relationship with peripheral facilities

- Catalyst feeding temperature for heating and cooling

- Flow of pressurization and depressurization source

- Matching with peripheral facilities, etc.

Regarding software, conditions change depending on properties of content, mixture or various purposes; detailed discussion is required

- Heating and cooling method

- Shaft seal (Gland packing/mechanical seal, etc.)

- Motor, reducer

- Applicable regulations, etc.

On top of general stainless steel and carbon steel we have delivered a lot of anti-corrosion materials including the followings:

• Titanium

• Titanium (containing palladium)

• Hastelloy

• Carpenter

• Zirconium

• Sicromal

• Incoloy

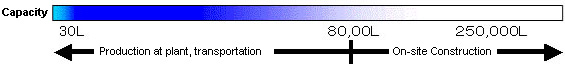

Until now, our company has provided a large number of stir flasks. The realistic results are provided as follows:

![]()

White part indicates approved range of production

We also have delivery records for mixing tanks that can allow the temperature from -80 to several hundreds ºC

In order to develop products with higher performance to contribute society, we have devoted ourselves and provided new products which are the results of our continuous efforts. Also, we are establishing an internal system to cope with issues of our customers. Please contact us if you have any technical difficulties.